Nemetschek Group Sanjay Gangal

Sanjay Gangal is the President of IBSystems, the parent company of AECCafe.com, MCADCafe, EDACafe.Com, GISCafe.Com, and ShareCG.Com. How BIM is Changing Bridge EngineeringJune 26th, 2020 by Sanjay Gangal

The bridge sector is lagging the building industry with respect to the use of BIM technology, although the number of structural components and data to be managed in bridge projects is usually considerably higher than in an average building project. The added complexity often leads to exploding costs or missed deadlines. We talked to Vanja Samec, General Manager of ALLPLAN Infrastructure and one of the leading visionaries in the Nemetschek Group on infrastructure. She explains why the industry needs more BIM and why Allplan Bridge should be recognized as the most advanced bridge solution on the market.  Vanja Samec, General Manager of Allplan Infrastructure. Copyright: ALLPLAN Infrastructure. SG: Congratulations on releasing Allplan Bridge 2020. How long have you been working on Allplan Bridge and what do you consider the main benefits? VS: Thank you. The congratulations are deserved for our entire enthusiastic team: engineers and developers with many years of experience in the bridge sector. Looking back, it was obviously a lot of work, but we knew what we wanted to develop, and we were using our long-term experience. We are proud that we created something, that the bridge industry was missing, and that is also required from authorities worldwide. It seems, that we hit the nerve of the bridge industry and its demands. As you might know, ALLPLAN is part of the Nemetschek Group, or the “Nemetschek Eco System” as we describe it. The Group is supporting innovations – in my opinion this is the key for long term success. Still we are empowered to maintain our identity and work very closely to our customers. When we think of “innovations” we do not refer to the flashy, shiny things that might become important for clients 5, 10 or 15 years from now. For us “true innovation” is things that help our clients right away.

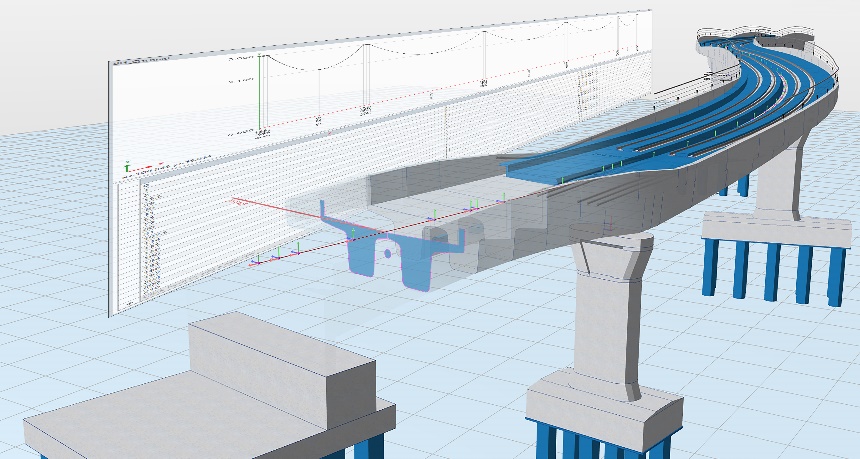

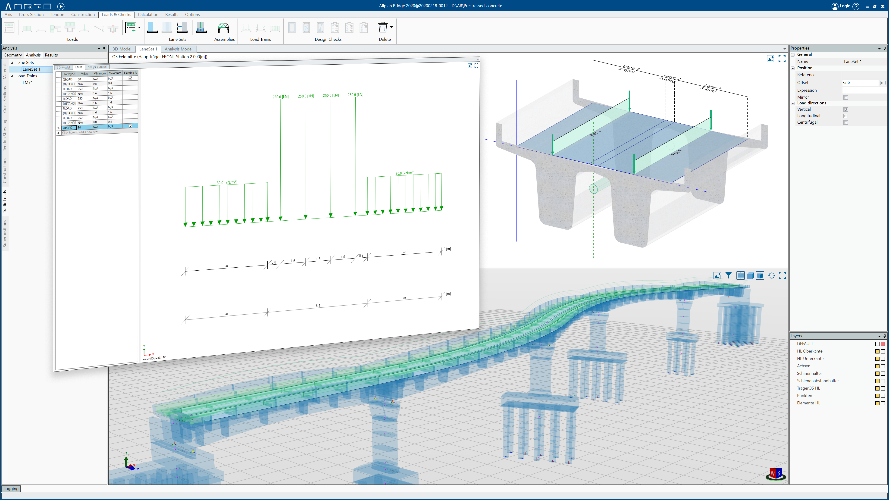

But to get back to your question: as part of our infrastructure strategy at ALLPLAN we decided to develop a completely new solution for 4D parametric bridge modeling, analysis, design, and detailing: Allplan Bridge. “Seamless collaboration” is what the whole Nemetschek Group is striving for and that is what we were trying to achieve with this project, too. Since April 2018, the new 3D parametric Allplan Bridge Modeler has been available as the first component of this solution. In October 2018, Allplan Bridge Prestressing followed to address prestressed bridge structures effectively and comprehensively and in April 2019 we added 4D construction schedule definition and calculation with a technical preview for linear analysis. Since October 2019, Allplan Bridge 2020 enables 4D parametric modeling, structural analysis and detailing in one single BIM solution. For the first time, the analytical model is automatically derived from the physical model. It’s the world’s first fully integrated solution that uses a common parametric model for both structural analysis and detailing. In April 2020 we even added the missing part – code-based design as a technical preview. The linking part between analysis and detailing. This is for sure the dream of every bridge engineer and designer.  Allplan Bridge 2020 is the world’s first fully integrated solution that uses a common parametric model for both structural analysis and detailing. Copyright: ALLPLAN Infrastructure. SG: We often hear that bridges are in a precarious condition and even collapse. What can we do to improve the quality of bridges? VS: The reasons for the poor condition of many bridges are different. Maintenance of bridge structures is very costly. Unavoidable weather conditions, temperature fluctuations and corrosion by road salt in winter play a role. The frequency and intensity of traffic loads is one of the important reasons. A further cause is the lack of quality of the bridge structure itself from the very beginning. This reason might lead back to design and construction. The reasons are diverse again: lack of time, inconsistent design data from different sources and formats etc. The crucial reason are also different individual bridge models and sources of truth for the same project (geometric, structural, tendon, construction, detailing), which do not match exactly. In individual cases, several models are used in parallel by teams distributed around the world. Based on all these reasons the wish would be working on one model only. Every modification would affect all models at once and the source of truth is one only. Of course, the quality of such a solution needs to be on the highest level – meaning not only in technology but technically as well. SG: What are the challenges for the bridge industry today? VS: Bridges are complex structures: in manner of complexity of the geometry and the high dependency of the structural behavior from construction sequences and erection techniques. Every change processed is therefore extremely laborious. Nevertheless, modifications as well as time-consuming synchronizations in bridge construction are part of daily business. Different stakeholders are involved in different life-phases of the bridge, so misunderstandings, errors and multiple entries of redundant data and possible inconsistencies may occur in cases of many “sources of truth”. For most bridge projects, variants for preliminary design will be developed: due to construction, cost and quality reasons. Comparison of variants to determine the best one in terms of quality are correspondingly time and labor intensive. Due to lack of time in the design process, these are often avoided or not sufficiently thought through. This might have a negative effect on the basic quality of the bridge. SG: What is the answer to all those hurdles? VS: What is needed to get a grip on the challenges is a “single source of truth”. It means that we need an intelligent 4D model including a variety of functionality required throughout the design and construction process. The bi-directional data exchange between BIM model and structural analysis is required. The digital model must suit all needs of the process, from the preliminary design phase via detailed design, detailing and construction to the operation phase throughout the lifetime. SG: How does the “single source of truth” affect bridge workflows? VS: The “single source of truth” is the central BIM model, which represents the parametric 3D geometry of the bridge, but also serves as an analytical model for static and dynamic calculations along the time axis. Any change to one of these models affects all phases in the life cycle of the bridge. Therefore, all information is preserved, and it is no longer necessary to create multiple models for different phases. Complex workflows with various project partners as well as contractors can be interlocked in a timely manner for all construction measures using BIM. This is what we from ALLPLAN, but also speaking for the Nemetschek Group as a whole, envision when we talk about “seamless collaboration”. This philosophy has yet another benefit for project owners: they are basically guaranteed that they will be able to work with the best partner for each and every discipline, because there is no limitation in regard to the tools required to work on a project.

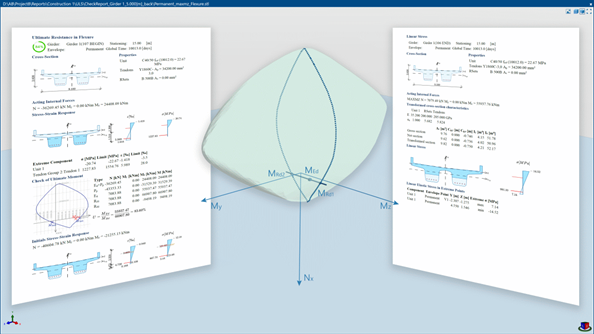

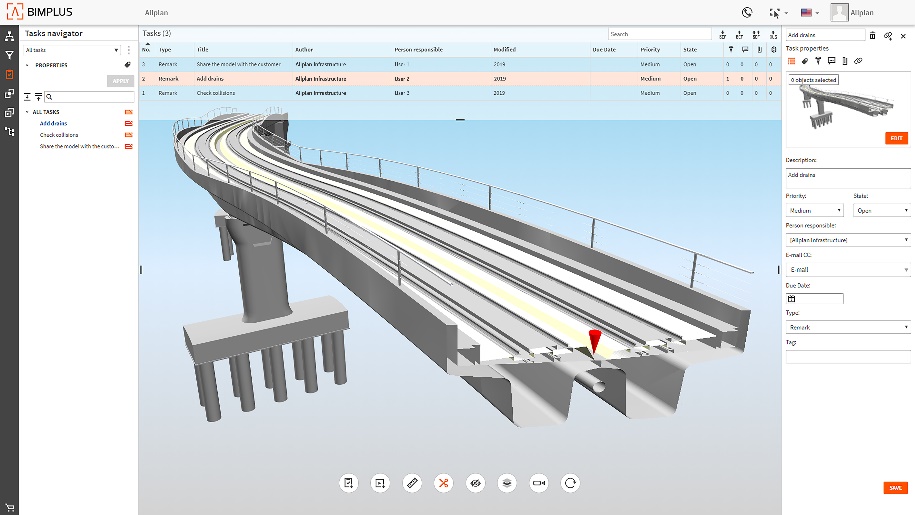

The Tamina Bridge in St. Gallen, Switzerland – a landmark project where Allplan Engineering was used. Copyright: Public Works Service of the Canton Sankt Gallen, ALLPLAN. BIM also means a change in data transfer, data requirements and the resulting workflows. With the OpenBIM approach, the different data formats are harmonized and all those involved in the design process can obtain information on the current status at any time. Inconsistencies and collisions become apparent in the design phase and can be eliminated in advance – not just on the construction site. In this way, time and cost overruns can be avoided and at the same time the quality of bridges can be optimized. SG: What are the biggest benefits for designers and engineers from working with Allplan Bridge? VS: Allplan Bridge is the new technical solution especially tailored for bridge engineering. The heart of it is the bridge modeler, based on a strictly parametric description of the bridge geometry. That means the model database contains design parameters and development rules rather than detailed geometric data in form of coordinates in space. The weight and the position of superimposed dead loads (like sidewalk, road pavement, etc.) are automatically retrieved from the geometrical model. A wide range of pre-stressing tendon types can be parametrically defined: with immediate or later bond, internal and external, longitudinal, transverse, and vertical, as well as with non-standard geometry. The modifications are incorporated only at their origin and all other linked members are automatically updated. For stress computations, the structure must be mathematically modeled in a suitable way to allow a mechanical analysis in accordance with accepted calculation methods and design code rules. This requires the adaptation of the geometric BIM model to a suitable computation model in accordance with beam or finite element theory. For Allplan Bridge we have applied all our experience in bridge engineering and the latest technology. Our developers are engineers and designers themselves. So, it is not just a marketing claim when we say that we are close to our customers and their needs. SG: What is so revolutionary about Allplan Bridge 2020? VS: With Allplan Bridge 2020 we managed to realize the “single source of truth”: the mathematical calculation model is automatically derived from the physical model. Design modifications throughout the planning process are always a crucial point, labor-intensive and error prone. With our new solution, bridge engineers and designers can meet these challenges: when the design is modified, the analytical model is automatically adapted (including all loads, construction sequences and tasks etc.). This greatly reduces the amount of work and the susceptibility to errors.  With Allplan Bridge 2020-1 users can define traffic loads in a very comfortable way. Copyright: ALLPLAN Infrastructure. Allplan Bridge 2020 enables very comfortable traffic load definition. On the one side, the traffic load is automatically applied in accordance with the selected standard, on the other side, the generic approach of live load definition allows the user to consider any type of moving load. The most unfavorable effects due to traffic loads can be determined quickly and easily. We are closing the gap between analysis and detailing with a technical preview of Code-based Design. After the global effects have been calculated and the corresponding envelopes generated, the user can perform the code-dependent design to determine the required reinforcement area. Once the reinforcement is definite (calculated or determined manually), the ULS checks can be carried out.  With Allplan Bridge 2020-1 the user can perform the code-dependent design to determine the required reinforcement area. Copyright: ALLPLAN Infrastructure. ALLPLAN is a pioneer of OpenBIM solutions. The analytical model generated in Allplan Bridge can be uploaded to the cloud-based BIM platform Allplan Bimplus. This allows to transfer the analytical model to other structural analysis solutions connected to Allplan Bimplus.  With the combination of Allplan and the cloud-based BIM platform Allplan Bimplus, everyone involved has access to the latest design, anytime, anywhere and with any device. Copyright: ALLPLAN Infrastructure. SG: What can we expect from Allplan Bridge in the future? VS: To sum up, Allplan Bridge is an innovative bridge BIM solution, serving the bridge industry during all life phases. User friendliness, efficiency, optimization and innovations are drivers of our development goals. The Nemetschek Group re-invests 25% of its annual revenue into R&D. Actually, and this is true for all brands of the Group, in some of our annual releases, up to 70% of the new features been added based on customer feedback. That underlines: we are listening to our user’s requirements and will continue working as engineers for engineers. By using a common bridge model instead of separate ones, interdisciplinary collaboration is improved. Allplan Bridge is a new generation BIM solution that will change the way bridge projects are designed and executed. The latest technology should ensure that engineers are not restricted in their freedom and creativity despite the high degree of automation. Our development roadmap is stable and fulfills the most important requirements of the bridge sector. We are planning modeling and analysis extensions – also dynamics will be included. Due to our internationality, different standard requirements will be embedded. As an OpenBIM solution provider we are also following the latest IFC requirements for bridges. Growing demands worldwide for our solution gives us a lot of interesting ideas, but also a very positive feeling and enthusiasm for future development. Category: Allplan |

|

|

|||||

|

|

|||||

|

|||||